Product Groups

- Aluminium profiles (standard)

- Aluminium profiles (special)

- Aluminium sheets (standard)

- Aluminium sheets (special)

- Aluminium made to measure

- Construction systems

- Industry systems

- Sign systems

- Postersystems

- EdgeLight systems

- LightBox systems

- Tensioning systems

- Fabric frames

- Signposting

- Advertising pillars

- C-Frame frames

- Standing - Terrace 50/75

- LED trough lights

- Mounting & installation

- Aluminium LED profiles

- ACP Edge trim profiles

- Cleaning & Service

- Varia-Click

- Advertising sign profiles

- Tube connecting systems

Comhan offers a wide variety of standard aluminium profiles. We have multiple different aluminium profiles for construction and extrusion profiles in stock. Are you looking for anodised profiles? These profiles are available in our extensive stock of profiles. We offer services to cut the aluminium profiles according to your wishes. For example, cutting aluminium piping to the desired size.

SPECIAL ALUMINIUM PROFILES

Besides the variety of standard profiles that we offer, we also have so-called special profiles. Aluminium trimming profiles, joining profiles and dividing profiles are a few examples.

CUSTOM SIZED PROFILES AND CUSTOMER SPECIFIC PROFILES

Do you need a custom job? Besides that standard profiles we offer custom aluminum profiles. Our specialists provide you with expert advice, which they can provide you with after years of experience working with aluminium. This way we can make sure that all the aluminium profiles are delivered according to your wishes.

Are you looking for a specific profile that can be found nowhere, simply because it is not in production yet. Comhan comes with the solution. Comhan has their very own design & engineering department where they can come up with specified solutions for your company.

Comhan can provide you with all custom orders and adjustments. It is even possible to make sure that we keep your custom profiles in stock. We always deliver “just in time” so that you always have the aluminium profiles at the exact time that you need it.

More information? Go to the customer-specific profiles page.

Aluminium profile customisation

We can do profile customisation for certain specialised adjustments and standardised profiles. For example with: sawing, CNC turning, milling and rolling, 3D-profile editing up to 6 metres, welding and dae-burring parts.

We can also deliver processed profiles with a finished surface. Anodise, powder coating, wet coating or stoving is not a problem at all.

Aluminium profiles: Our product

General advantages our aluminium profiles are:

-

Medium strong alloy;

-

Proper corrosion protection;

-

Properly anodisable;

-

Weldability, decreasing of strength;

-

Typical profile alloy.

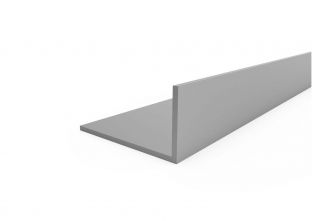

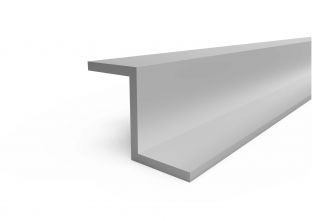

ALUMINIUM CORNER PROFILES

An aluminium corner profile, or a so-called L-profile, is called like this because it could be used within many different industries. Corner profiles could be used for interior and exterior finishes, strengthening, support, hood supports or as construction parts for industrial manufacturing of products and constructions.

Corner profiles could be an equilateral or an unequal design which says something about the flanges. Which could be of different lengths.

Aluminium corner profiles could also be called ‘standard extrusion profiles’. This says something about the way they are manufactured, by extrusion and almost always evenly lengthened at 6 metres. Standard corner profiles are developed with the alloy EN AW 6060 T66; they can also be made out of aluminium sheet metal with cutting and typesetting. Dimensions of the pins or flanges could also be variabel. However, the maximal lengths will always be 4 metres.

Aluminium corner profiles could be used in construction, industrial and visual communication branche.

Depending on the usage, different surface finishes are possible; this could be of functional purposes, decorative or embellishment as lacquering, spraying, baking, powder coating, brushing or anodising.

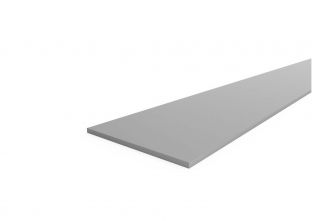

ALUMINIUM FLAT BAR OR STRIP

An aluminium standardised profile could also be called a flat bar. This profile can be obtained by extrusion in alloy EN AW-6060 T66 (AIMgSi). The standard size of a flat bar is 6 metres. In combination with other standardised profiles, a flat bar is a necessary profile with the manufacturing of all kinds of profiles and construction jobs. Flat bars could be used finished or unfinished as skirting boards, connecting strips, lifting anchors, anchor plates or coupling plates. The usage possibilities are limitless.

Aluminium flat bar is available as a standardised profile from thin and small sizes (10 x 2.0 mm) up to thick and back sizes (200 x 20.0 mm). Besides the possibility to cut the flat bar or strip from aluminium sheet metal (unprocessed, brute, lacquered or anodised), it could also be welded, glued, screwed or riveted.

If a flat bar should be thicker, or specially alloyed than cutting it from thick sheet metal is a possible alternative option. The exact size, length and thickness could be variable but they come with a maximal length of 4 metres.

Aluminium flat bars could be used in construction, industrial and visual communication branche.

Depending on the usage, different surface finishes are possible; this could be of functional purposes, decorative or embellishment as lacquering, spraying, baking, powder coating, brushing or anodising.

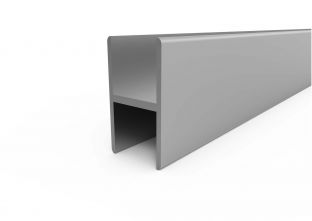

ALUMINIUM U-PROFILES

Aluminium u-profiles got their name because of their shape; the capital letter U. The big diversity and the different thicknesses available provides these profiles with a lot of usage possibilities. Because of the standardised alloy EN AW-6060 T66 (AIMgSi) and the weldability of the aluminium U-profile, makes it a necessary part of welding and construction work. Small U-profiles could be used as a panel, sheet or edge finish. The bigger sizes are primarily used with different types of construction and welding jobs for example: stiffeners, load-bearing construction parts, gutters and other combinations. U-profiles are mostly combined with standardised profiles to be used as carriers, connection profiles, as roof supports, mounting beams, gutters and guide rails. Aluminium U-profiles are primarily used with the construction of windows and doors (facade construction).

Aluminium U-profiles can also be called “standardised profiles” and are pointing to the way they are being manufactured by the means of aluminium extrusion. Other aluminium profiles are: corners, flat bars, tubes, rectangular tubes, circular tubes, T-profiles, Z-profiles and H-profiles, with the exception of round bars and square bars. Aluminium U-profiles can be used as aluminium sheet metal through the means of cutting and typesetting. The dimensions of the base and the legs can be variable; (width x height) with a maximum length of 4.0 metres.

Aluminium U-profiles could be used in construction, industrial and visual communication branche.

Depending on the usage, different surface finishes are possible; this could be of functional purposes, decorative or embellishment as lacquering, spraying, baking, powder coating, brushing or anodising.

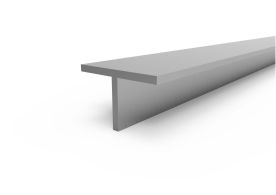

ALUMINIUM T-PROFILES

The aluminium T-profile is easy to recognise due to its T-shaped appearance; the capital T. An indispensable aluminium "standard profile" which is used in making all kinds of (rear) constructions, frames and other structures. Due to the standard EN AW-6060 T66 (AlMgSi) alloy and due to the good weldability, aluminium T-profiles can be used as anchoring profiles, supporting profiles as coupling profiles or coupling posts and also as a table top, edge or panel finish.

Aluminium T-profiles are more limited in terms of dimensions when compared to the Angle, Flat, U-profile and tubes. Aluminium T-profiles are made by extrusion (are pressed) usually and have a standardised commercial length of 6 metres. The Aluminium flat bar is used in construction, industry, visual communication and related sectors.

Depending on the usage, different surface finishes are possible; this could be of functional purposes, decorative or embellishment as lacquering, spraying, baking, powder coating, brushing or anodising.

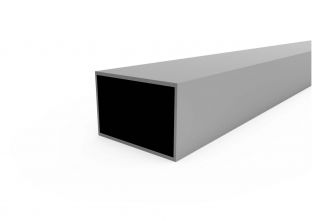

ALUMINIUM TUBES AND RECTANGULAR TUBES

The enormous diversity and the possible dimensions of aluminium tubes and rectangular tubes (from very small to very large) offers countless, completely different areas of application. Aluminium tubes can also be called rectangular tubes or rectangle pipes and they are made by means of aluminium extrusion and they have typically a standardised commercial length of 6 metres. A tube is an equilateral profile where all sides have the same dimensions. As the name suggests, a rectangular tube or rectangular pipe is a hollow chamber profile.

Depending on the chosen dimensions and application, aluminium tubes are very rigid and torsion-resistant. Because of the standardised alloy EN AW-6060 T66 (AlMgSi) and the weldability, aluminium tubes are in fact indispensable for making all kinds of welding. It can be used with construction work, slat frames, cultivation tables, machine housings and various structures in construction, industry and in the communication industry.

For example, aluminium tubes are used in the manufacturing of (self-)supporting construction parts, facade construction frames, facade fabric tensioning systems, rear constructions and roof supports in the construction and sun protection industry.

Aluminium tubes are also widely used as a construction material in bodywork and the horticultural sector. For example, for making spans and for growing tables. Welded constructions, frames, racks, stiffeners and combinations thereof, can all be made with tubes, often in combination with other standardised profiles.

Depending on the usage, different surface finishes are possible; this could be of functional purposes, decorative or embellishment as lacquering, spraying, baking, powder coating, brushing or anodising.

ALUMINIUM ROUND TUBE

The enormous diversity and the possible dimensions of aluminium circular tubes (from very small to very large) offers countless, completely different areas of application. Aluminium tubes are made by means of aluminium extrusion often at standard trade length of 6 metres. An aluminium round tube is a so-called hollow chamber profile. Due to the standard alloy EN AW-6060 T66 (AlMgSi) and the good weldability, aluminium tubes are indispensable in making all kinds of welding, construction work and in the communication industry.

Aluminium round tubes are used in the manufacture of (self-)supporting constructional parts, advertising frames, cable ducts, masts, machine shielding, fencing, risers, stair protection, fall-through protection, anti-burglary racks, shop displays and drains. Welded constructions, frames, racks, stiffeners and combinations thereof, can all be made with aluminium round tubes, often in combination with other standard profiles. Welded constructions, frames, racks, stiffeners and combinations thereof, can all be made with aluminium round tubes, often in combination with other standard profiles.

Depending on the usage, different surface finishes are possible; this could be of functional purposes, decorative or embellishment as lacquering, spraying, baking, powder coating, brushing or anodising.

ALUMINIUM H-PROFILES

Aluminium H-profiles are easy to recognise by the shape of a capital "H". An aluminium “standard profile” used in making structures, frames and other structures. Due to the standard alloy 6060-T66 it provides good weldability. Aluminium H-profiles can be used as coupling profiles, intermediate posts, edge finishes or as panel edging.

Aluminium H-profiles are somewhat more limited in terms of usage and applicability compared to the "normal" standardised profiles such as Angle, Flat, U-profiles and Box profiles. H-profiles are made by means of aluminium extrusion (pressed) and usually have a length of 6 metres. Aluminium H-profiles are widely used in construction, industry and in the communication sectors.

Depending on the usage, different surface finishes are possible; this could be of functional purposes, decorative or embellishment as lacquering, spraying, baking, powder coating, brushing or anodising.

ALUMINIUM Z-PROFILES

Aluminium Z-profiles are easy to recognise by the shape of a straight capital letter “Z”

An aluminium “standard profile” that can be used as a finishing profile when making all kinds of constructions, frames, welds or structures. Due to the standard alloy 6060-T66 and proper weldability, aluminium Z-profiles can be used as carrier profiles, a finishing or suspension profile, as a coupling profile or as intermediate posts for roof and conservatory finishing.

Aluminium Z-profiles have more limitations in comparison with the more standardised profiles. Corner, flat, U and circular profiles are made by means of aluminium extrusion and have a length of 6 metres. Aluminium Z-profiles can be used as aluminium sheet metal through the means of cutting and typesetting. Dimensions could differentiate in size, but they have a maximal size of 4 metres. The Z-profile is used in construction, industry, visual communication and related sectors.

Depending on the usage, different surface finishes are possible; this could be of functional purposes, decorative or embellishment as lacquering, spraying, baking, powder coating, brushing or anodising.

ALUMINIUM BARS

General advantages our aluminium bars are:

-

Strong alloy;

-

Good corrosion protection;

-

Moderate to good anodisable;

-

Good weldability;

-

Good machinability;

-

Poorly deformable.

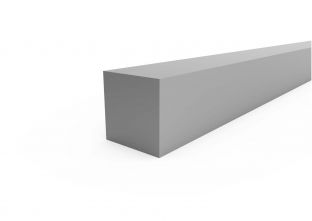

ALUMINIUM SQUARE BAR

The aluminium square bar can also be called “a full bar square” or “a solid aluminium bar”. It is an aluminium extrusion profile in an EN AW-6082 T6 (AlSi1MgMn) alloy which can be used for various purposes. The profile is easy to weld and can also be easily machined by CNC turning and/or milling. Aluminium can withstand low temperatures, conducts heat and electricity very well, is non-magnetic and non-toxic. Because of these unique properties the aluminium square bar is often processed through CNC machines and these parts can often be used within machines, electronics, instruments and construction machines.

In the facade construction industry, the aluminium bar is used, for example, to make dowel pins, hoisting or adjusting anchors to attach facade cassettes and/or heavy glass facade elements to a concrete store floor and to adjust it if necessary. The aluminium square bar is manufactured in a standardised length of 6 metres for the smaller dimensions and manufactured in a length of 3 metres for the somewhat larger dimensions.

ALUMINIUM CIRCULAR BAR

Aluminium round bar is also known as a “full bar round” or a “solid aluminium round bar”. An aluminium extrusion profile of an EN AW-6082 T6 (AlSi1MgMn) alloy that can be used for various purposes. The base is easily weldable and can also be machined easily by CNC turning and/or milling. Aluminium can withstand low temperatures, the material is a very good conductor of heat and electricity, is not magnetic and is also non-toxic. Due to these unique product properties, the circular bar is regularly CNC machined into parts to be used in, for example, the machine, electronics, instrumentation and machine building industry.

In the facade construction industry, the aluminium bar is used, for example, to make dowel pins, hoisting or adjusting anchors to attach facade cassettes and/or heavy glass facade elements to a concrete store floor and to adjust it if necessary. The aluminium square bar is manufactured in a standardised length of 6 metres for the smaller dimensions and manufactured in a length of 3 metres for the somewhat larger dimensions.